The path towards an electric future is hampered by the ability of batteries to provide sufficient power over a sufficiently long period of time. Globally considerable research is going into methods to improve battery power, including the use of graphene.

Research from Chalmers University of Technology shows how a graphene sponge can help lithium sulphur batteries reach a new potential. The interest with lithium sulphur batteries is due to these types of batteries offering a theoretical energy density some five times greater than that of lithium ion batteries.

To help to bring this type of battery to fruition, Swedish researchers have constructed a catholyte (the portion of the electrolyte in the immediate vicinity of the cathode in an electrolytic cell) using a graphene sponge.

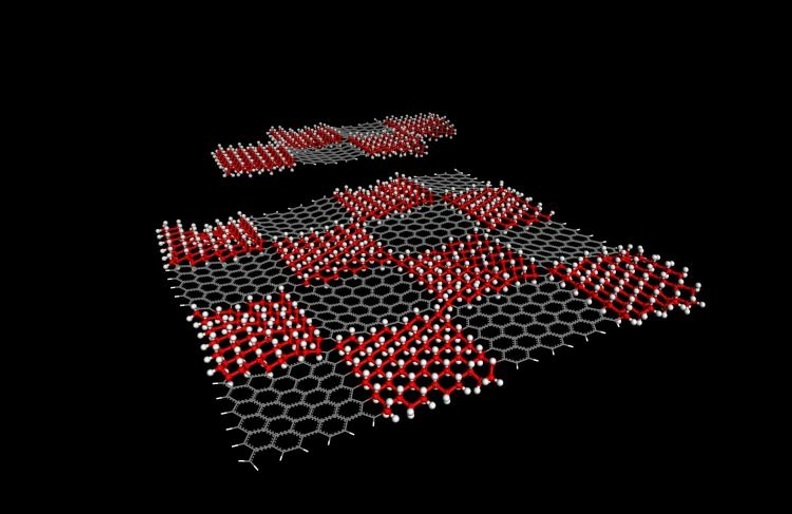

The application uses a porous, sponge-like aerogel (derived from reduced graphene oxide). Graphene oxide is a special material that can acts as a single monomolecular layer of graphite with various oxygen-containing functionalities.

This aerogel acts as a free-standing electrode positioned within the battery cell. The function is to enable a better and higher utilisation of sulphur. An aerogel is a synthetic porous and ultralight material formed from a gel, where the liquid component has been replaced with a gas. This creates a product with efficient thermal conductivity.

The breakthrough came following experiments where the battery cathode and electrolyte were combined into one liquid (the ‘catholyte’). This reduces battery eight and enables more rapid charging and improved power capabilities. This was further strengthened by using the graphene aerogel.

This worked, as principal scientist Carmen Cavallo explains, by taking “the aerogel, which is a long thin cylinder, and then you slice it – almost like a salami. You take that slice, and compress it, to fit into the battery.” Once the sulphur-rich solution (catholyte) is added the aerogel functions as a support, soaking up the sulphur solution much like a sponge. This boost efficiency by allowing the sulphur to cycle back and forth without any major losses. The research demonstrated an 85 percent capacity retention after 350 battery charge-discharge cycles

Read more: New organic battery can operate for decades

The research is published in the Journal of Power Sources, with the research paper titled “A free-standing reduced graphene oxide aerogel as supporting electrode in a fluorine-free Li2S8 catholyte Li-S battery.”