The next-generation ion engine that may one day send American astronauts to Mars has passed a major milestone. Working in coordination with NASA engineers from Glenn Research and the Jet Propulsion Laboratory, Aerojet Rocketdyne says it has completed its early systems integration test of the Advanced Electric Propulsion System (AEPS) 13-kW Hall thruster that is it building for NASA, clearing the way for further development.

A major hurdle for NASA’s ambitions to return to the Moon and to mount manned deep space missions is the required propulsion system. Chemical rockets are already at the outer edge of their theoretical limits and nuclear thermal engines are still primitive and many largely theoretical. However, recent missions, like NEXT and the Dawn mission to the asteroid Ceres, have demonstrated that ion thrusters with their low fuel loads and high efficiency could be a viable near-term solution as well having wider propulsion applications.

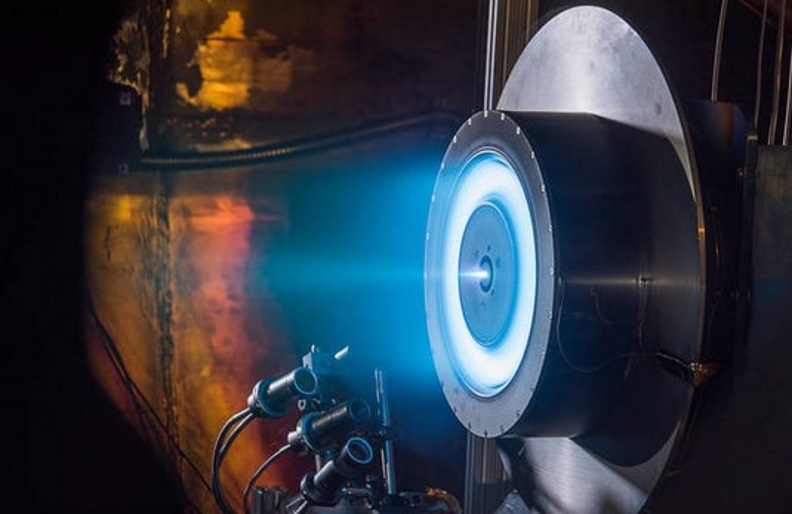

Under contract, Aerojet Rocketdyne is working on AEPS with an emphasis on the ion thruster, power processing unit, low-pressure xenon flow controller, and electrical harness – all of which will be powered by solar panels once in space. By using what will one day be a 50-kW ion drive, which uses electrons captured in magnetic fields to ionize xenon molecules and accelerate them to very high velocities, NASA hopes to increase thruster efficiency by a factor of 100 and double the thrust of current electric propulsion systems.

These AEPS thrusters could have a number of applications, most notably for NASA’s Gateway manned deep space orbital outpost, as well as for deep space missions, or even the first manned Mars expeditions.

According to Rocketdyne, the recent tests were of the AEPS Hall thruster’s power elements, which include the discharge supply unit (DSU) and the power processing unit (PPU). Using breadboard versions of the units hooked up to a NASA development ion thruster, tests were conducted in a thermal vacuum chamber at NASA’s Glenn Research Center in Cleveland, Ohio. This revealed that the DSU and PPU could successfully convert power with high efficiency and minimal waste heat.

With the early systems integration tests over, Aerojet Rocketdyne engineers are moving on to the design finalization and verification phase leading up to the critical design review (CDR) and eventual production.

“By staying on the cutting edge of propulsion technology, we have positioned ourselves for a major role not only in getting back to the Moon, but also in any future initiative to send people to Mars,” says Eileen Drake, Aerojet Rocketdyne CEO and president. “AEPS is the vanguard for the next generation of deep space exploration and we’re thrilled to be at the mast.

“Our AEPS discharge supply unit performed exceptionally, yielding significant conversion efficiency improvements important for future demanding missions. These results are a testament to the Aerojet Rocketdyne team’s focus and dedication to advancing the state of the art in this critical in-space technology area.”

Source:

Aerospace Rocketdyne